BOFA Filters

Replacement Filters Part No. (Laser Industry)

BOFA AD Access

A1030153 - BOFA DeepPleat pre filter

A1030154 - BOFA Combined HEPA / Gas filter

BOFA AD Fusion

A1030167 - BOFA DeepPleat pre filter

A1030298 - BOFA Combined filter

BOFA AD 250

A1030056 - BOFA DeepPleat Pre Filter

A1030055 - BOFA Combined HEPA / Gas Filter

BOFA AD 350

A1030056 - BOFA DeepPleat Pre Filter

A1030055 - BOFA Combined HEPA / Gas Filter

BOFA AD Nano

A1030190 - BOFA DeepPleat DUO pre filter

A1030191 - BOFA Combined filter

BOFA AD Nano Plus

A1030190 - BOFA Pre filter

A1030191 - BOFA Combined filter

BOFA AD Universal

A1030167 - BOFA DeepPleat Pre Filter

A1030166 - Combined Filter

BOFA AD Oracle SA iQ

A1030344 - BOFA Pre filter

A1030155 - BOFA Combined filter

BOFA AD Oracle iQ2

A1030156 - BOFA DeepPleat DUO pre filter

A1030155 - BOFA Combined filter

BOFA AD Oracle iQ

A1030156 - BOFA DeepPleat DUO pre filter

A1030155 - BOFA Combined filter

BOFA AD 500 iQ

A1030222 - BOFA DeepPleat DUO pre filter

A1030297 - BOFA Combined filter

BOFA AD 1000 iQ

A1030222 - BOFA DeepPleat DUO pre filter

A1030297 - BOFA Combined HEPA/Gas filter

And many more.

Replacement Filters Part No. (Electronics Industry)

BOFA TVT 2

A1030087 - BOFA Pre Filter

A1030086 - BOFA Combined filter

BOFA T 1

A1030087 - BOFA Pre Filter

A1030086 - BOFA Combined filter

BOFA T 15

A1030095 - BOFA Pre Filter

A1030094 - BOFA Combined filter

BOFA T 30A

A1030093 - BOFA Pre Filter

A1030399 - BOFA Combined filter

BOFA T 60

A1030165 - BOFA Pre Filter

A1030164 - BOFA Combined filter

BOFA T 100

A1030165 - BOFA Pre Filter

A1030164 - BOFA Combined filter

BOFA V 300E

A1030108 - BOFA Pre filter (Pack of 5)

A1030266 - BOFA HEPA / Gas combined filter

BOFA V 350E

A1030110 - BOFA Filter set

BOFA V 200

A1030102 - BOFA Pre filter (Pack of 5)

A1030099 - BOFA Combined filter

BOFA V 250

A1030102 - BOFA Pre filter (Pack of 5)

A1030099 - BOFA Combined filter

And many more.

Pre filters

The pre filter is designed as a barrier, to capture the larger dust and particulate, protecting the HEPA filter from premature blocking.

BOFA offer a range of pre filters, all designed for different applications and processes, depending on the amount of dust being extracted.

The efficiency of the pre filter is directly related to the life of the HEPA in that the more particulates captured in it, the less can pass through and prematurely block the HEPA. Most pre filters have an efficiency grading of F5 - F7.

HEPA filters (High Efficiency Particulate Arresting)

HEPA filters used by BOFA are of the mini pleat design. They are generally manufactured by specialist filter companies to ensure that the latest manufacturing and test methods are adopted. Each filter incorporates a series of webbing between the pleats. This feature not only guarantees even spacing for full filter coverage between each pleat, but also alleviates the possibility of airflow vibration or collapse.

Filters should be individually tested and certified to a minimum efficiency of 99.995% down to 0.3 microns.

The BOFA ADVANTAGE micro filters are positioned within the system in such a way that all the particulates are not only captured but held within the media.

This is not the case with conventional reverse airflow systems where particulate can fall away and rest on the outside of the pre filter creating a health risk on filter replacement.

Mini pleats can be produced with depths of up to 200mm within each pleat, depending on the application.

BOFA HEPA filters are tested to filter 99.997% @ 0.3 microns.

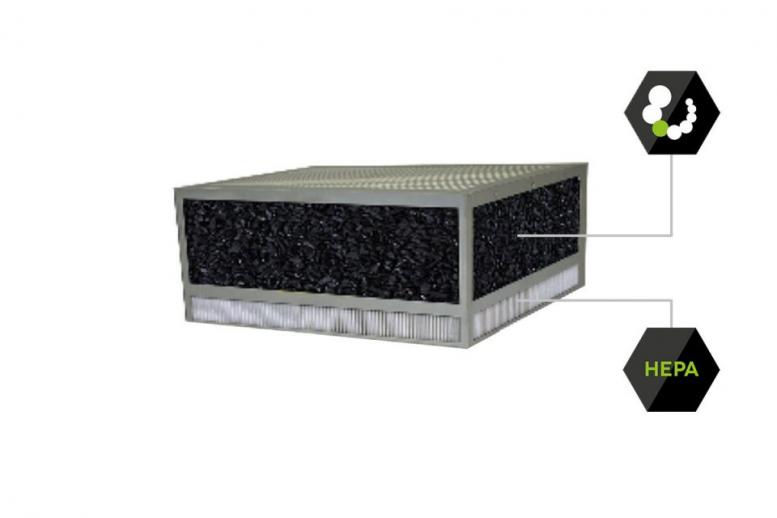

Advanced carbon filter (ACF) technology

BOFA’s combined filters are a combination of a HEPA filter and a chemical/gas filter coupled together to create a more compact, cheaper and more effective solution. This joint filter method extends across most of the BOFA products creating a safer, cleaner system.

Please contact us for more information.